Starting a new sewing project is exciting, but there’s nothing worse than being stopped in middle by problems such as skipped stitches, shredded or frayed threads, or broken needles. The good news, is that you can avoid many of these problems just by using the right kind of thread! Keep reading below to find out some great information to set you up for success.

Thread Type

When searching for just the right thread, there’s so much more to think about than just the color! And don’t be fooled by discounted threads found in the “bargain bin.”

Higher quality threads will give you less trouble while sewing, and will give you a beautifully finished product that will hold up and last longer over time.

Poor quality thread is much more likely to break, and also produces a lot more lint. You might not think it’s a big deal, but all that extra lint can really clog up your machine, and if you’re not cleaning it regularly, that cheap thread can cost you a lot down the road when you have to get your machine serviced!

Annie’s favorite is Superior Thread’s So Fine! #50. It’s a great, lint-free, polyester thread that works great for quilting and bag-making.

For more information about the different fiber types and styles of threads, read this great article from Superior Threads: Thread Characteristics. This is a good start for finding out which ones will work best for your particular projects!

Thread Size / Weight

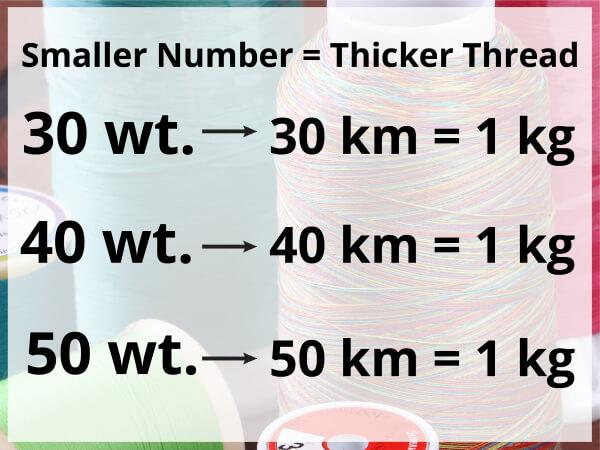

I’m sure as you’ve looked at spools of thread, you’ve noticed numbers such as 30 wt., 40 wt., and 50 wt., etc. But what do those numbers mean? This refers to the length of thread found in a certain quantity of weight.

For example, if a thread is labeled 30 wt., it means there are 30 kilometers of thread that weighs 1 kilogram. A finer thread, such as 50 wt., would have 50 kilometers in that same 1 kilogram bundle.

Bottom line: the thicker the thread, the smaller the number.

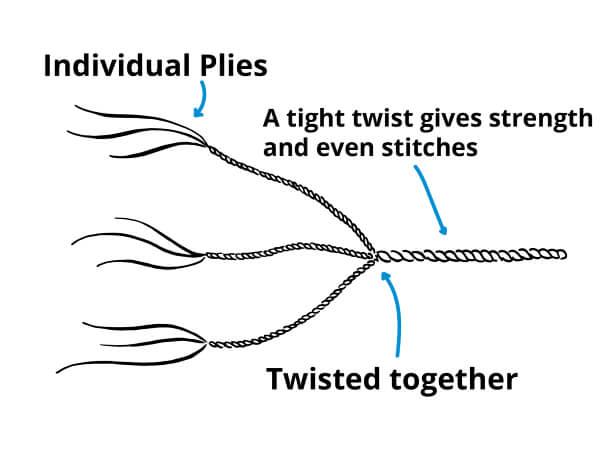

Perhaps you’ve seen other numbers listed, such as 50/2 or 50/3. While you may think they’re the same thread, they’re very different!

The first number refers to the weight or thickness, as discussed above. The second number refers to the number of strands or plies that are twisted together during manufacturing. The more plies wound together, the stronger your thread will be!

Still not sure which thread is right for you? We suggest taking a look at this really handy chart created by Superior Threads. They’ll give you recommendations for everything from quilting to embroidery, to bobbins or applique!

Thread Direction

Ever wondered which spool pin to use on your machine? Take a closer look at the type of thread you have!

If the thread is cross-wound (which means the thread comes off the spool from the top), use the horizontal spool pin.

If the thread is stacked (which means the thread comes off the spool from the side), use the vertical spool pin!

Cones vs. Spools

Buying cones of thread is a great option for a couple of reasons:

1. You’ll have plenty of thread on hand for all your projects. A typical spool of thread has anywhere between 600-1,420 yds of thread, and a cone has anywhere between 2500-3,280 yds. So, for example, one cone could be the equivalent of having 3 or 4 different spools!

2. It can be much more economical to buy in “bulk.” A lot of the cost of a spool of thread is in the winding process, so the larger the spool, the more money you’re going to save!

Don’t forget, if you’re buying cones, you may need to buy a thread stand, since the spool pin on your machine isn’t big enough to hold the cone.

*Fun tip: If you don’t have circle rulers, try tracing around a thread cone in order to round edges on bags and purses!

Storage and Care

The best way to make your threads last for years to come, is to keep them out of direct sunlight. The harmful UV rays can fade the colors and may cause some threads to become brittle over time.

Another tip is to try and keep your threads as clean as possible. Keep threads in a drawer or plastic bin, away from air vents or places where they’re exposed to dust or other fibers (such as pet hair). The dust won’t necessarily harm the threads themselves, but running all that dust through your machine can cause problems.

If you have a stash of very old threads and you’re not sure if they’re still good to use, take a small sample (approx. 6-12”) and try pulling it apart. If you get a clean break, the thread is still good to use. If it shreds or pulls apart like a cotton ball would, then it’s best to throw it out.

Needles

As you learned above, there are many different types, weights and sizes of threads. Because of this, you’ll want to make sure you use the right sized needle for the job. Click HERE to read a great article from BERNINA, about the different sizes of needles and what they’re best used for.

Here at ByAnnie, we use #90/14 Topstitch needles almost exclusively, and especially like Superior Threads Titanium Coated Superior Needles. We like topstitch needles because they have a groove down the shank, which prevents thread from shredding. They’re also strong and sturdy and work really well for fabric quilted with ByAnnie’s Soft and Stable. Best of all their eye is twice as big as the eye on a universal needle. Take a look at this infographic for more details!

Machine Tension

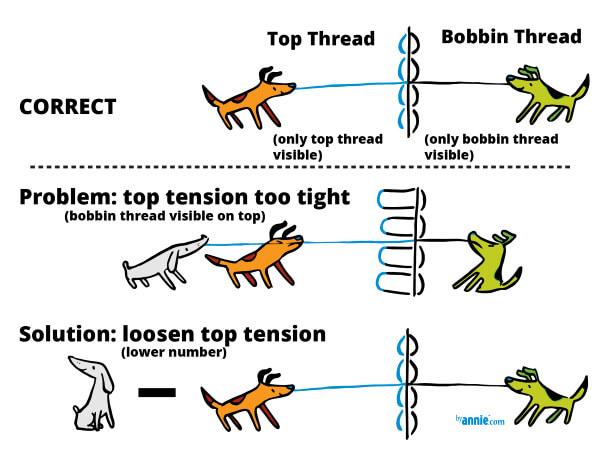

Sewing machines generally have their tension dials preset when they come from the factory.

Depending on what type or weight of thread you’re using, you may need to adjust the tension to make sure your stitches come out evenly.

Superior Threads gives an example of how tension is like a tug of war. If everything is adjusted correctly, you should have nice, even stitches on top and on bottom.

If one of the sides is too tight, you’ll start seeing the excess “slack” from the other side start to show through.

For example, if you’re seeing your bobbin thread come through on top, then you’ll know the tension is too tight and you’ll want to loosen it up.

Happy Stitching!

We hope you've learned a few new tips about threads. Let us know what your favorite threads are and how you use them!

All About Thread